The major parameters of pressure, ultrasonic applying time, holding time and mold temperature are utilized at 0.2 MPa, 2 s, 5 s, 60 ☌, respectively. As a result, the miniature products are successfully obtained by ultrasonic injection molding. Heater is also inserted in the injection mold for controlling the temperature of the injection mold. The injection mold of miniature parts was designed and manufactured for producing the tensile samples with PA6. Aluminum 7075 alloy is used for fabricating the ultrasonic horn.

#LATIN HYPERCUBE SAMPLING FOLLOWED OPTIMIZATION FULL#

The ultrasonic horns vibrating at 20 kHz in both cases of half wave length and full wave length are designed by finite element method. In this work, the miniature tensile sample of polyamide 6 (PA6) is produced by using the ultrasonic injection molding process. According to the data set of 1–30, the optimum values of the temperature difference, maximum temperature, and the pressure drop are found 28.88 K, 361.35 K, and 0.46 bar, respectively. The proposed hybrid LHC-DT approach achieves reliable and apparent results for all multiple objectives so that the Pareto frontier of the data set of 1–30 is selected for assessment. The multi-dimensional decision-making procedure is completed with multiobjective optimization. Since the computational time is a crucial factor, we perform the hybrid LHC-DT approach with four different data simulation set of 1–30, 1–60, 1–90, and 1–134.

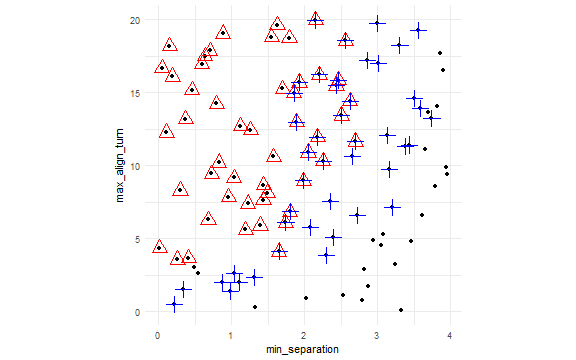

Hence, we present the hybrid Latin Hypercube (LHC)-Delaunay Triangulation (DT) method to create meta-model data effectively at high dimensions by using 134 different simulations in the MATLAB environment. The high number of design variables results in an unaffordable computational load for full factorial design. This study aims to design a complex conformal cooling channel (CCC) structure for an injection mold geometry that has eight different design variables according to multiple main objectives of the maximum temperature at the plastic interface, the difference between the maximum and minimum temperatures at the internal wall, and the pressure drop in the channel.

0 kommentar(er)

0 kommentar(er)